In a world where environmental sustainability and cost savings are king, Cummins Inc. has made a giant leap forward with its revolutionary approach to remanufacturing engine parts. The company’s ReCon® remanufactured parts and engines are setting new standards in eco-friendly and economically viable solutions, proving that it’s possible to breathe new life into engines while being kind to both the planet and the pocketbook.

The Remanufacturing Rundown:

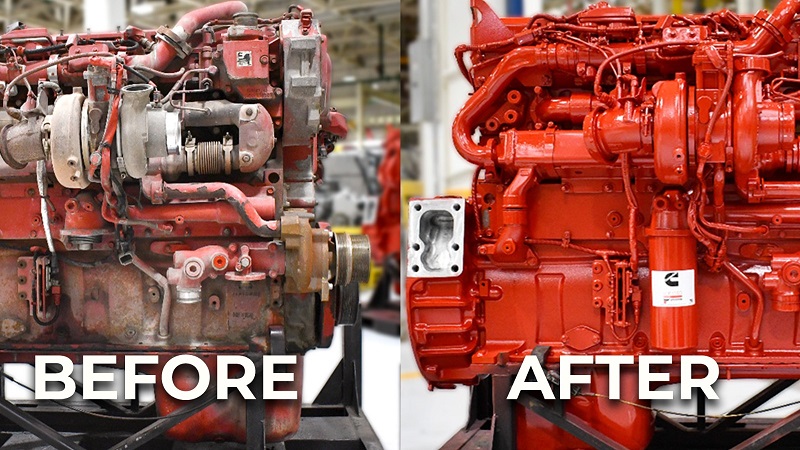

Cummins isn’t playing around when it comes to remanufacturing. Their ReCon parts, originally from Cummins engines, undergo a meticulous process of disassembly, inspection, cleaning, calibration, and testing. This rigorous routine ensures these parts perform on par with brand new Cummins parts, but with the added bonus of being more wallet-friendly.

Engine Overhaul: The Cummins Way:

Imagine an engine reaching its golden years, being completely disassembled and every part painstakingly prepared for a second shot at life. Cummins does exactly this, employing state-of-the-art cleaning technologies such as laser cleaning for rust and enzyme methods for stubborn grease and oil. After a thorough clean-up, each part undergoes a rigorous inspection, with techniques like ultrasonic testing ensuring everything meets the original Cummins quality standards. Even better, any upgrades to the original design are included, giving these old engines a modern twist.

Decades of Perfection:

Cummins’ journey in perfecting remanufacturing spans decades, incorporating advanced techniques like additive manufacturing (3D printing), collaborative robots (cobots), and laser cleaning. This isn’t just a repair job; it’s an entire engine transformation, ensuring each part is examined, cleaned, and tested to meet stringent performance requirements.

A Wide Range of Renewal:

Here’s a fun fact: up to 85% of an engine can be remanufactured. From turbochargers and fuel pumps to actuators and cylinder heads, there’s a vast array of parts getting a second lease on life. And for those parts that can’t join the remanufacturing party, they’re replaced with new or ReCon parts.

Eco-Friendly and Economical Excellence:

Cummins’ remanufacturing process is a beacon of hope in advancing the circular economy. It’s about reusing, recycling, and remanufacturing to reduce waste, conserve resources, and tackle environmental challenges like climate change. Cummins ReCon engines and parts align perfectly with the company’s PLANET 2050 strategy, emphasizing their commitment to a sustainable future.

The Advantages of Going ReCon:

Remanufactured engines from Cummins aren’t just reliable; they’re also a more affordable alternative to their brand-new counterparts. This cost-effectiveness comes from the reduced need for new materials, energy, and water in the remanufacturing process. Plus, these engines come with the latest engineering updates and a Cummins warranty to boot.

Boosting Industry and Community:

The remanufacturing process doesn’t just benefit the environment and customers; it positively impacts industry dynamics and local communities. By reusing existing materials and products, the need for raw material extraction and waste disposal decreases, reducing carbon-intensive processes. It also creates local jobs, as skilled technicians are essential for meticulously restoring parts to their original glory.

Challenges on the Road to Remanufacturing:

Despite its numerous benefits, remanufacturing faces challenges, particularly in aligning with suppliers. It requires a synergy between manufacturing and sustainability goals, and overcoming historical hesitations about the quality and longevity of remanufactured products.

Cummins ReCon stands at the forefront of remanufacturing innovation. Its engines and parts embody reliability, affordability, and a vision for a sustainable future. While challenges like supplier alignment and industry acceptance persist, the undeniable benefits of remanufacturing make it a key player in shaping an eco-friendly, economically viable, and resilient manufacturing marketplace.

To join the remanufacturing revolution, contact your local Cummins distributor or authorized dealer and discover how ReCon parts and engines can help achieve your sustainability goals.