January 12, 2024, Sanand, Gujarat – Tata Passenger Electric Mobility Ltd. (TPEM), a branch of the esteemed Tata Motors, has inaugurated its state-of-the-art manufacturing plant in Sanand, Gujarat. Celebrating this achievement, the first Tata car was ceremoniously rolled out from the new assembly line. This event, graced by TPEM’s Managing Director, Shailesh Chandra, along with senior leaders from the Passenger and Electric vehicles divisions, signifies a momentous leap for the company.

Shailesh Chandra, who leads both Tata Motors Passenger Vehicles Limited and TPEM, expressed his pride at this accomplishment. “Seeing the first car emerging from the new TPEM facility is a landmark moment for us. Within a record time of 12 months, we’ve upgraded this factory, preparing it for a diverse array of current and future models,” Chandra stated. He extended his gratitude to the Government of Gujarat and the dedicated workforce, crediting them for this achievement. Chandra believes this facility will be instrumental in propelling Tata Motors and TPEM to new heights.

Chandra further elaborated on Tata Motors Passenger & Electric Vehicles business’s growth trajectory, emphasizing the company’s commitment to sustaining this momentum with a solid lineup of “New Forever” products and a focus on electric vehicles. The new Sanand facility, with an initial capacity of 300,000 units annually, expandable to 420,000, is poised to meet increasing demands, complementing existing capacities nearing saturation.

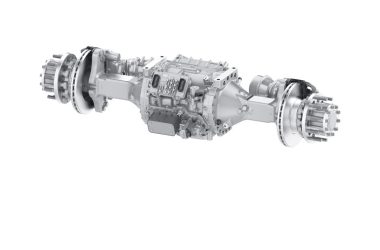

The facility, formerly owned by Ford India and acquired on January 10, 2023, spans 460 acres and is situated in GIDC Sanand, a prime industrial area with a strong supplier network. This plant, Tata Motors’ second in Gujarat, is designed to produce both ICE and EV models and features four major sections: Stamping, Body construction, Paint, and Final assembly. Each section boasts high levels of automation and cutting-edge technology for precision manufacturing.

Significant technological enhancements have been implemented across the facility, including new dies in the Press shop, upgraded lines and additional robots in the Weld shop, modified systems in the Paint shop for robotic painting and waxing, and revamped handling systems in the Assembly shop.

Currently employing over 1000 staff and technicians, the plant is set to create an additional 1000 jobs within the next 3-4 months, aligning with production expansion plans. Committed to employee development, Tata Motors has invested in educational programs ranging from diplomas to master’s degrees. Echoing Tata Motors’ dedication to sustainability, the facility features a 50 KW solar rooftop. It is a water-neutral plant, aiming to achieve water positivity by December 2024.