Pune, India – If automotive components could sweat, they’d be trembling right now. ZF Group in India has just bagged a trio of landmark orders that will push powertrains, tires, and possibly engineers to their limits. Leading the charge is India’s first-ever 440 kW Differential Unit Test Bench — a machine so powerful, it could make even the most stubborn gearbox confess its secrets.

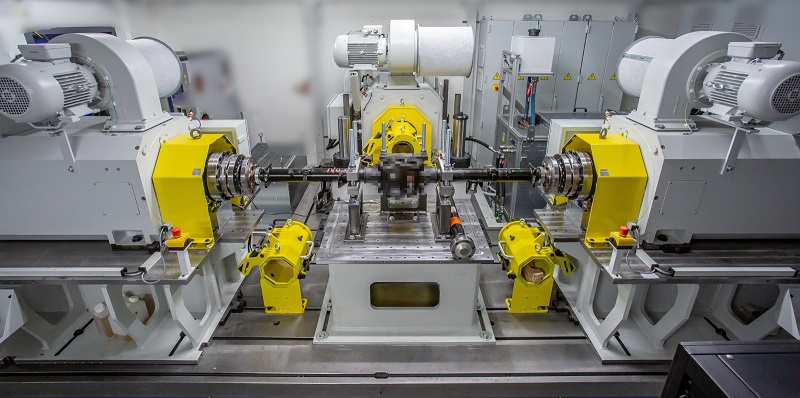

This engineering heavyweight features a low-inertia input dyno for high dynamic applications, and a direct shaft connection to the Device Under Test (DUT) — meaning no pesky gearboxes or chain systems in between to soak up power or introduce measurement errors. In plain English: more accuracy, less mechanical gossip. Plus, with its movable dyno providing horizontal adjustments, it can accommodate almost any DUT with the kind of flexibility a yoga instructor would envy.

The rest of the order is no small feat either: eight tire test benches for Indian tire manufacturers, including rolling resistance testers, endurance machines, high-speed rigs, and end-of-line systems to ensure every tire leaving the factory is road-worthy — or at least road-confident.

“This is a proud moment for ZF as we bring our advanced testing technology to India,” said Akash Passey, President, ZF Group India. “These orders not only set a new benchmark but also serve as a reference point for future projects in the region.”

Beyond the tech specs, these projects plant ZF firmly in the driver’s seat of India’s next-gen mobility movement. Whether it’s for autonomous driving, e-mobility, or ensuring your tires don’t chicken out at 120 km/h, ZF’s test systems promise to keep vehicles safe, efficient, and performance-ready in all weather conditions.

In short, ZF isn’t just testing parts — it’s testing the limits of what Indian automotive manufacturing can achieve. And so far, the results look like a pass with flying (and maybe slightly speeding) colours.